At CIRCULAR CARBON, we have implemented a system that carbonizes clothing, including synthetic fibers, without sorting, minimizing CO₂ emissions and recycling it into soil conditioners and new materials. We are transforming companies' “disposal costs” into “recycling value” and expanding the circular economy with partners across industries. We are changing the reality where 470,000 tons are incinerated annually, offering sustainable options for both the environment and business. Join us in redesigning the future of clothing and participating in the cycle of regeneration.

Landfilling ash and soot leads to

environmental harm.

All carbonized materials are

fully recycled into products and

soil improvement materials.

In Japan, approximately 470,000 tons of clothing are discarded each year, most of which are disposed of through incineration or landfill. As companies strive toward ESG management and reducing CO₂ emissions, they face the challenge of “wanting to recycle, but lacking concrete means.”

This issue of mass clothing waste has become a significant barrier to achieving a sustainable society.

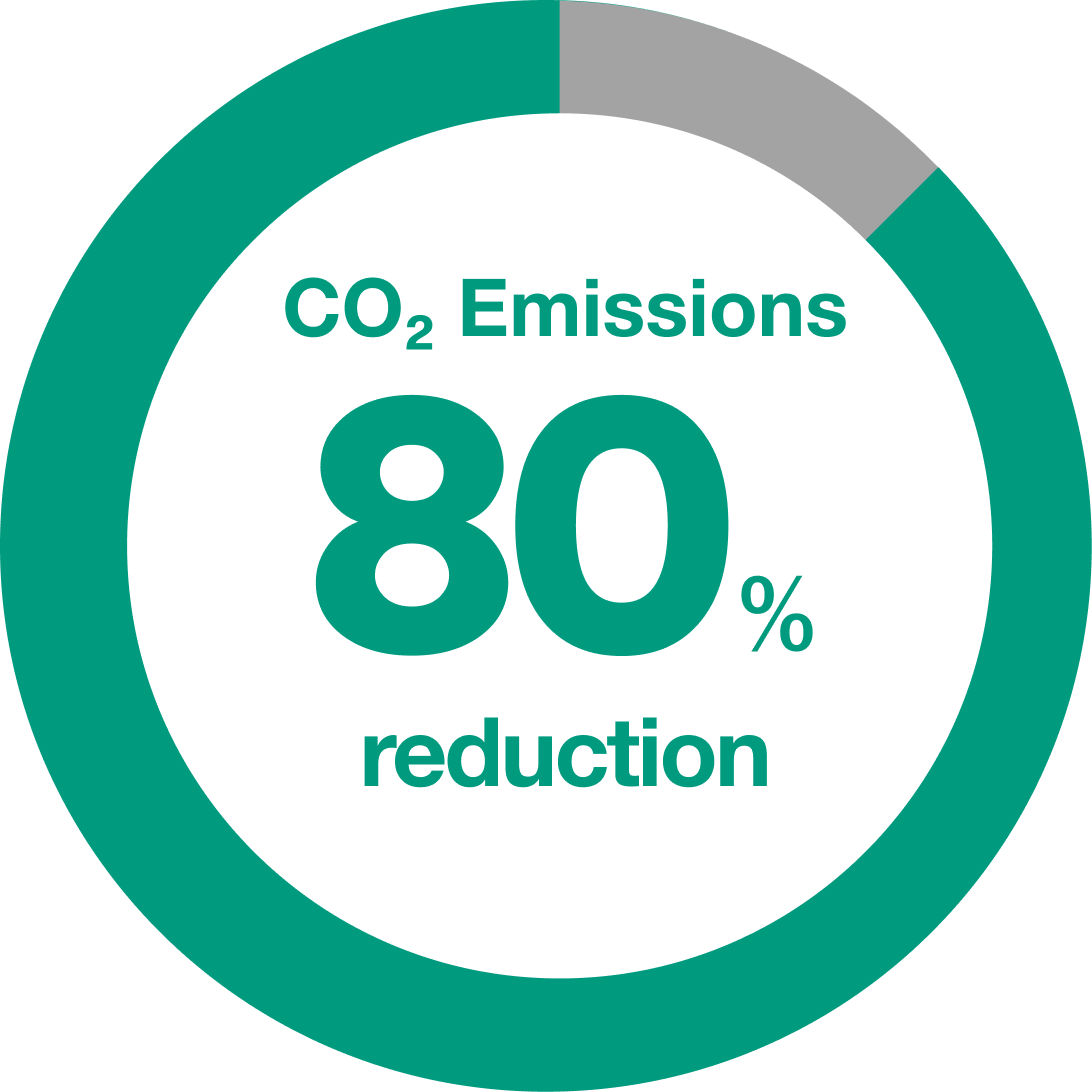

CO₂emisions

Annual

The incineration of Over-disposal clothing results not only in the generation of hazardous substances, but also in the emission of greenhouse gases such as CO₂, making it a significant cause of environmental pollution and climate change.

Reducing CO₂ emissions by about 80% through safe carbonization of clothing.

With existing recycling technologies, it has been difficult to separate natural and synthetic fibers in clothing, making large-scale processing a challenge. CIRCULAR CARBON’s unique technology enables the recycling of all types of clothing — including those containing synthetic fibers — without the need for separation. Garments that were once discarded are now reborn as valuable resources that contribute to sustainable agriculture.

After automatically removing accessories such as zippers and buttons, the fibers are processed into an optimal form using proprietary technology and then moved into the carbonization stage.

Through a carbonization system that applies high-temperature thermal decomposition, harmful substances and microfibers contained in synthetic fibers are safely broken down and transformed into high-quality carbonized material.

The resulting carbonized material is utilized as a soil conditioner, serving as a valuable resource that contributes to sustainable agriculture.

The carbonized material produced possesses unique properties such as a porous structure and carbon-centered stability, creating new value. Its primary application is as a soil conditioner for farmland and horticulture, where it promotes the activation of soil microorganisms. In addition, it holds potential for a wide range of uses — from construction materials and absorbents to products with deodorizing and humidity-control functions.

FIBER

POWER

FARM

MATERIALS